Introduction: The Precision Agriculture Imperative

The global food system faces a confluence of unprecedented challenges: climate volatility, diminishing arable land, and a rapidly growing population. Traditional agriculture, while foundational, is increasingly resource-intensive and susceptible to external shocks. In response, a new paradigm of food production has emerged: Controlled Environment Agriculture (CEA). Infarmight stands at the forefront of this revolution, not merely as a farm, but as a highly sophisticated, bio-digital engineering system.

This post delves into the core technical and scientific principles that underpin Infarmight’s operations. Its success is not a matter of chance, but the result of a synergistic integration of advanced mechanical engineering, data science, plant biology, and chemical kinetics. For the curious audience, this is a technical explanation of how Infarmight transforms a modular structure into a high-yield, hyper-efficient food production engine.

Section 1: The Physical Infrastructure – Controlled Environment Architecture

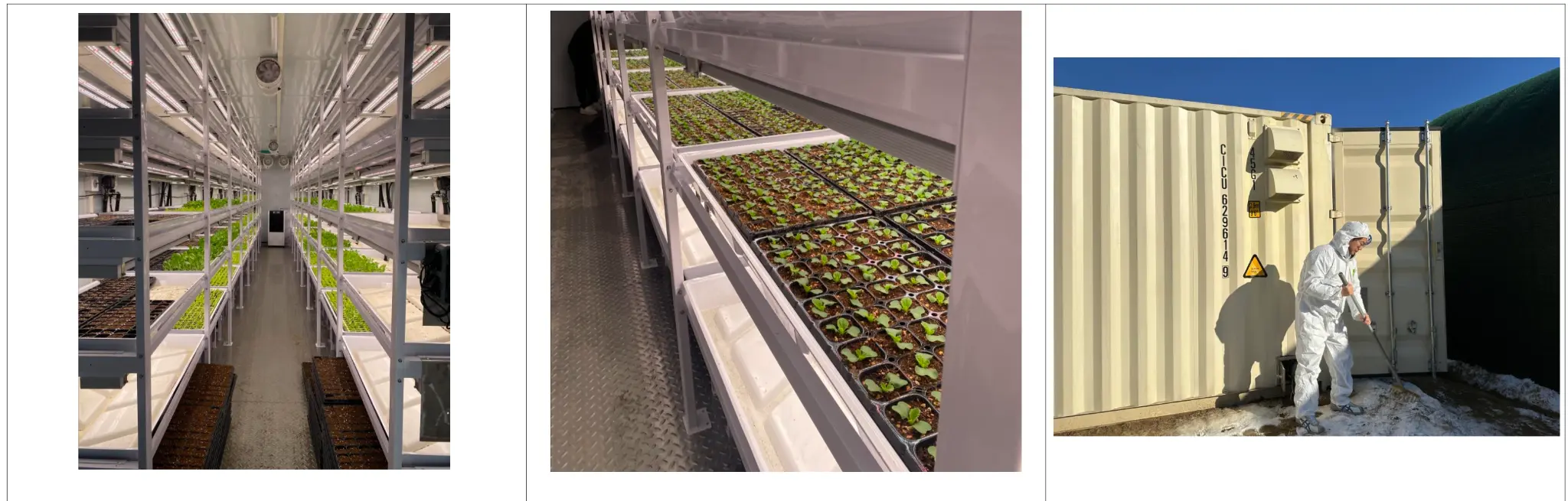

Infarmight’s physical presence is defined by its modular, vertical farming units. These are not simple greenhouses; they are hermetically sealed, climate-controlled biospheres designed for maximum spatial and resource efficiency.

1.1 Vertical Farming Systems and Modularity

The core design principle is modularity. Each Infarmight unit, or “farm,” is a self-contained ecosystem, allowing for rapid deployment and scalability. The vertical stacking maximizes the Crop Per Area (CPA) ratio, significantly reducing the land footprint compared to conventional farming. The structural integrity and material science are engineered to minimize thermal transfer, which is critical for energy efficiency in climate control.

1.2 Hydroponic Nutrient Film Technique (NFT)

Infarmight primarily utilizes a variation of the Nutrient Film Technique (NFT) for its nutrient delivery system. In this closed-loop system, a very thin film of nutrient-rich water flows over the roots of the plants, providing hydration, oxygen, and essential minerals.

The technical advantages of NFT include:

- High Oxygenation: The shallow stream ensures the root mat has excellent access to atmospheric oxygen, preventing root rot and promoting vigorous growth.

- Water Efficiency: The closed-loop recirculation system achieves up to 95% less water usage than field farming, as water loss is limited almost entirely to plant transpiration.

- Precision Control: The system allows for rapid adjustment of the nutrient solution’s chemical composition, a necessity for the AI-driven optimization discussed later.

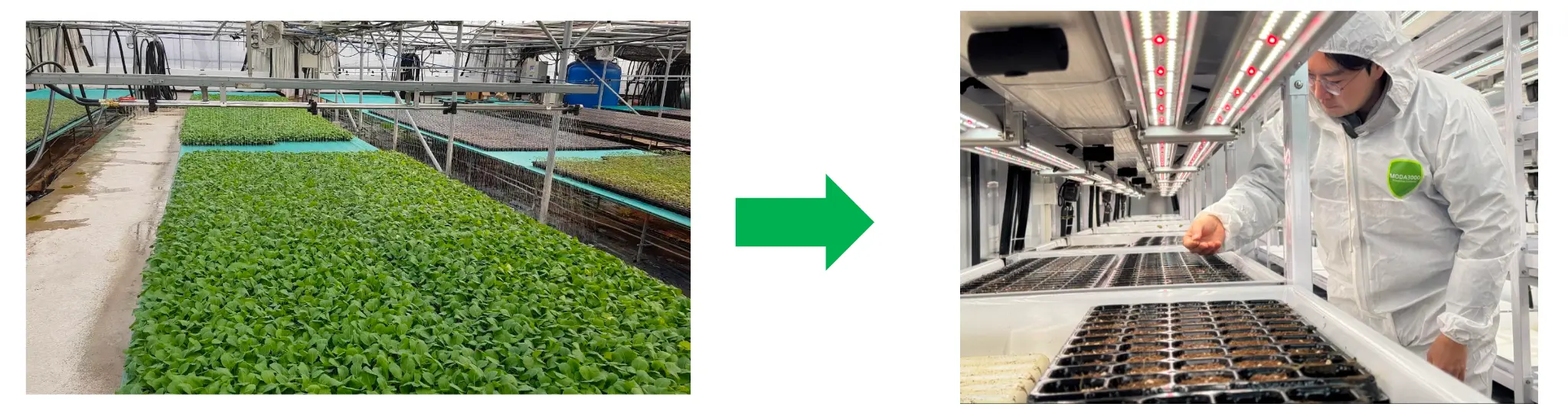

The image below illustrates the dense, controlled environment typical of a vertical farm, where every cubic meter is optimized for production.

1.3 Advanced HVAC and Climate Control

Maintaining a perfect microclimate is paramount. The Infarmight system employs a sophisticated Heating, Ventilation, and Air Conditioning (HVAC) system that goes beyond simple temperature regulation.

- Vapor Pressure Deficit (VPD) Management: Instead of just controlling temperature and relative humidity (RH) separately, the system targets an optimal Vapor Pressure Deficit (VPD). VPD is the difference between the amount of moisture the air can hold when saturated and the amount of moisture it currently holds. Controlling VPD is a more accurate way to regulate the plant’s transpiration rate, which directly impacts nutrient uptake and growth.

- CO2 Enrichment: Plants in a sealed environment quickly deplete CO2. Infarmight injects CO2 to maintain levels significantly higher than atmospheric concentration (typically 800-1500 ppm), maximizing the rate of photosynthesis (the CO2 fertilization effect).

Section 2: The Biological Engine – Optimized Plant Growth

The true science of Infarmight lies in its ability to precisely control the two most critical inputs for plant life: light and nutrients.

2.1 Spectrally Tuned LED Lighting: The Light Recipe

Light is the energy source for photosynthesis. Infarmight replaces the sun with custom-engineered LED arrays. This allows for spectral tuning, where the light spectrum is tailored to the specific needs of the crop at different stages of its life cycle.

| Wavelength (nm) | Color | Biological Function | Infarmight Application |

|---|---|---|---|

| 400-500 | Blue | Chlorophyll synthesis, stomatal opening, compact growth | Early vegetative stage, structural development |

| 600-700 | Red | Photosynthesis, stem elongation, flowering/fruiting | Primary driver of biomass, late-stage growth |

| 700-800 | Far-Red | Shade avoidance response, leaf expansion | Used to control plant architecture and harvest time |

| 500-600 | Green | Penetrates canopy, can be used for human inspection | Minimized for efficiency, but used for specific photomorphogenic effects |

The system dynamically adjusts the Photosynthetic Photon Flux Density (PPFD) and the spectral ratio (e.g., Red:Blue ratio) based on the AI’s growth model, ensuring maximum Daily Light Integral (DLI) without inducing photoinhibition.

2.2 Nutrient Solution Management (Chemometrics)

The nutrient solution is a precisely balanced cocktail of macro-nutrients (Nitrogen, Phosphorus, Potassium) and micro-nutrients (Iron, Boron, Zinc, etc.). The science of maintaining this balance is called chemometrics.

- Electrical Conductivity (EC): This measures the total concentration of dissolved salts (nutrients). The system uses high-precision EC sensors and automated dosing pumps to maintain the optimal EC for the crop, which changes as the plant grows.

- pH Regulation: The pH of the solution affects the solubility and availability of nutrients. Infarmight’s system constantly monitors pH and automatically injects acid (e.g., nitric acid) or base (e.g., potassium hydroxide) to keep the pH within a tight, crop-specific range (typically 5.5 to 6.5).

- Nutrient Depletion Modeling: The AI tracks the differential uptake of individual ions by the plants and predicts future depletion rates, allowing for proactive, rather than reactive, replenishment of specific nutrient stocks.

Section 3: The Digital Brain – AI and Data Science

The physical and biological systems are managed by a centralized, intelligent control system—the digital brain of Infarmight. This is where the “smart” in smart farming truly resides.

3.1 Sensor Networks and Data Acquisition

Each farm is blanketed with a dense network of sensors, creating a continuous, high-resolution data stream.

- Environmental Sensors: Measure air temperature, RH, CO2, and light intensity (PPFD).

- Root-Zone Sensors: Measure solution temperature, EC, and pH.

- Imaging and Spectral Sensors: High-resolution cameras and multispectral sensors capture images of the plants. These images are processed to determine key phenotypic traits, such as leaf area index (LAI), chlorophyll content (via NDVI), and early signs of stress or disease.

This massive data acquisition system generates terabytes of data daily, which is transmitted to the cloud-based Infarmight Growth Platform.

3.2 The Infarmight Growth Model (Digital Twin)

The collected data feeds into a sophisticated Digital Twin of the farm. This is a virtual, real-time replica of the physical environment and the biological processes within it.

The core of the Digital Twin is a suite of machine learning models:

- Predictive Growth Models: Deep learning models, trained on years of historical growth data, predict the plant’s biomass, nutritional content, and final harvest date under various environmental conditions.

- Anomaly Detection: Unsupervised learning algorithms constantly scan the sensor data for deviations that indicate equipment failure, pest infestation, or nutrient imbalance, often identifying issues hours or days before a human could.

- Recipe Optimization: Reinforcement learning is used to iteratively refine the “growth recipe” (light spectrum, EC, VPD setpoints) to maximize yield, flavor, or nutritional density, depending on the desired outcome.

3.3 Automated Decision-Making and Feedback Loops

The AI’s primary function is to close the control loop. It translates the predictions and optimizations from the Digital Twin into immediate, precise control commands for the farm’s actuators (pumps, valves, LEDs, HVAC).

A typical feedback loop:

- Observation: Spectral sensor detects a slight drop in chlorophyll content (stress indicator).

- Analysis: The Growth Model diagnoses a potential Iron (Fe) deficiency based on the spectral signature and current EC/pH.

- Action: The AI commands the nutrient dosing system to inject a precise, calculated amount of an Iron chelate solution into the reservoir, followed by a minor pH adjustment to ensure optimal Fe uptake.

- Verification: The system monitors the spectral sensor data over the next 24 hours to confirm the correction was successful.

Section 4: Engineering for Scale and Sustainability

The technical ingenuity of Infarmight extends beyond the farm unit itself, encompassing the entire operational and environmental footprint.

4.1 Resource Efficiency Metrics

Infarmight’s design is fundamentally driven by efficiency, which is quantified through rigorous engineering metrics:

- Water Use Efficiency (WUE): As noted, the closed-loop system dramatically reduces water consumption. The only water lost is through plant transpiration and a small amount of evaporation, which is often recaptured by the HVAC system.

- Energy Use Efficiency (EUE): While vertical farms are energy-intensive due to lighting and climate control, Infarmight optimizes EUE through:

- High-Efficacy LEDs: Using LEDs with a high Photosynthetic Photon Efficacy (PPE), maximizing light output per watt.

- Heat Recovery: The heat generated by the LEDs and other electronics is often recovered and used to help maintain the ambient temperature, reducing the load on the heating system.

4.2 System Redundancy and Reliability

For a food production system, downtime is unacceptable. Infarmight’s engineering incorporates multiple layers of redundancy:

- Distributed Control: While a central AI optimizes the global network, each farm unit has an edge computing device capable of running essential control algorithms autonomously, ensuring basic life support (water, light, temperature) even if the network connection is temporarily lost.

- Sensor Calibration: The system employs self-calibrating sensors and redundant sensor arrays. Discrepancies between sensor readings trigger an automated recalibration or a flag for maintenance, ensuring the data feeding the AI is always accurate.

4.3 The Future: Decentralized Farming and Edge Computing

Infarmight’s modularity is key to its decentralized strategy. By placing farms directly in or near urban centers, the company dramatically reduces the food miles and the associated carbon footprint of transportation.

This decentralized network requires a robust, scalable IT architecture. The system leverages Edge Computing, where data processing and control decisions happen locally at the farm unit, minimizing latency and bandwidth requirements. The cloud platform acts as the central repository for model training and global optimization, constantly pushing updated, more efficient growth recipes back out to the edge devices.

Conclusion: The Synthesis of Science and Agriculture

Infarmight represents a profound shift in how we think about food production. It is a system where the laws of physics, chemistry, and biology are precisely managed by the power of data science and engineering. From the spectral tuning of LED light to the chemometric precision of the nutrient solution and the predictive power of the Digital Twin, every component is a testament to the application of rigorous science.

This technical synthesis allows Infarmight to deliver not just higher yields, but a more resilient, sustainable, and predictable food source, moving agriculture from a practice of reactive management to one of proactive, intelligent control. The science behind Infarmight is the blueprint for a food system ready for the 21st century.